The Dell Concept Luna is easily disassembled so Dell can reuse parts

What do you do if your laptop screen cracks or keyboard breaks? After some troubleshooting, you will probably throw the machine away and upgrade it. But what if some of your laptop’s components could be assembled and placed in another computer, like some Frankenstein creation? That’s exactly what Dell has in mind with its Concept Luna laptop project.

Concept Luna

According to the UN Global E-Waste Monitor 2020, only 17.4 percent of the 53.6 million metric tons of e-waste generated in 2019 was recycled. One of the sustainability goals that Dell wants to achieve by 2030 is to reuse or recycle an equivalent product for every product a customer purchases, with more than 50 percent of product content made up of recycled or renewable materials. And how will he get all these recyclable materials? Partially from Dell customers.

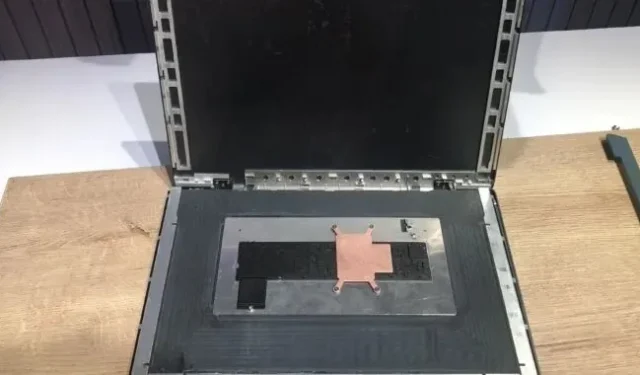

Last week I was able to test the Concept Luna. Announced today, a laptop designed to help Dell meet its environmental goals by offering parts that are easier to repair, reuse and recycle. The machine is designed to open easily so you can assemble its motherboard or other parts for use in future systems. Dell hopes that this process will allow the motherboard to be used on up to three machines.

One of the highlights here is that the Concept Luna’s motherboard sits behind the display. This is common with detachable laptops, but not with clamshells like the Concept Luna. The location of the motherboard means the machine cannot be actively cooled, so Dell had to improve the thermal performance of the system.

“Moving that smaller motherboard towards the top cover brings it closer to a larger surface area exposed to cooler outside air,” explained Glen Robson, CTO of the Dell Client Solutions Group, in a blog post today. “This, combined with separating it from the battery charger at the base, results in better passive heat distribution and can eliminate the need for a fan entirely.”

A Dell rep opened the Concept Luna laptop in front of me, and the process looked simple enough. By removing four screws, the Dell rep was able to remove two keystones before disassembling the computer and unplugging one cable to remove the motherboard.

The part about disconnecting via one cable is also important. The Concept Luna disassembly process should be easy enough that regular users won’t be too intimidated to use it.

Robson said that it should take about 1.5 hours less time to disassemble, repair and reuse the main parts.

In addition to the motherboard, Dell designed the laptop palm rest with refurbishment and reuse in mind. The keyboard comes out simple, but a Dell spokesperson noted that keyboards are likely to have fewer life cycles due to how much they go through.

On the outside, the laptop uses an aluminum chassis made by a hydropower plant. Extruded aluminum “requires less energy and generates less waste,”Robson said.

Green Goals

Dell built the Concept Luna to be repairable with recycled parts, but its original design was made with environmental considerations in mind.

During the event, Dell pointed to its 7300-year-old Latitude as an example. Motherboards represent 75 percent of the environmental waste generated to create this product. For a stable PC, Dell has reduced the size of the motherboard by 75 percent compared to the Latitude 7300 Anniversary Edition, making it “smaller”at 5,580 square millimeters, according to Robson, and has also reduced the number of components by about 20 percent. Dell said it cuts the motherboard’s carbon footprint in half overall.

In addition, Dell used flax fiber for the PCB backing instead of plastic laminates; the whole thing is held together by a water-soluble polymer.

Dell also claims that the Concept Luna could lead to less power-hungry devices by allowing the use of smaller batteries with an “advanced deep cycle cell.”. .still powerful enough for everyday use,” Robson said.

However, not all details will be able to find a second life.

Leave a Reply